Laser displacement sensors are the industrial world’s precision rulers — but unlike steel rulers, they never touch the part, never wear out, and can measure down to the micron. From inspecting automotive brake rotors to checking the flatness of smartphone screens, these devices help factories maintain quality without slowing production.

This guide explains what they are, how they work, the different types, and how to select and install them effectively. It’s written with practical examples so you can immediately apply the insights to real-world production.

What is a laser displacement sensor?

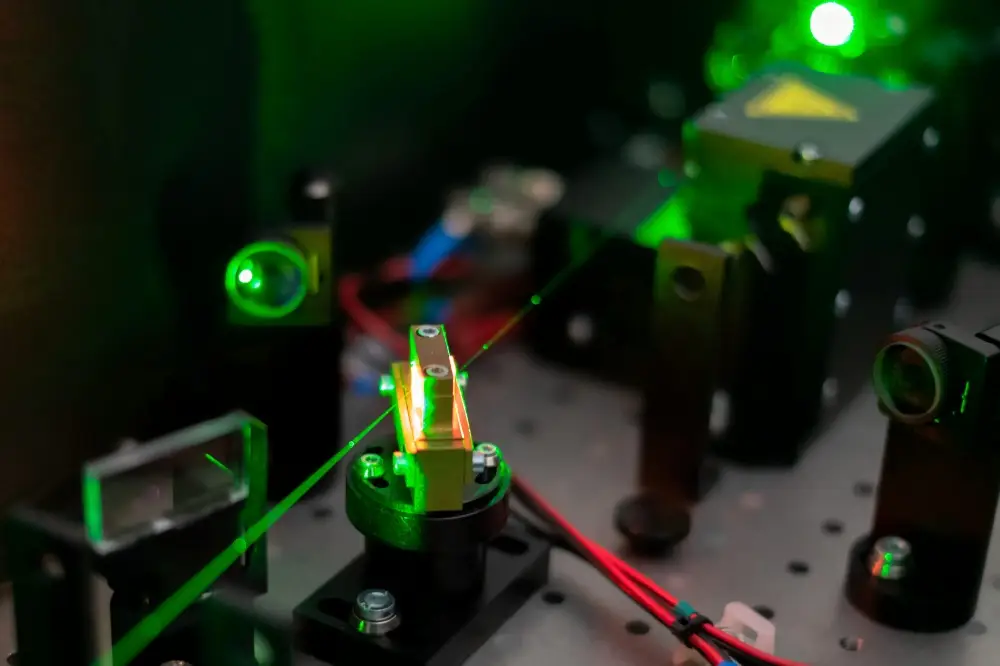

Using a projected laser beam and reflected light analysis, laser displacement sensors determine the distance between the device and a target object.

Key characteristics:

- Non-contact measurement – Ideal for fragile, fast-moving, or hot surfaces.

- High precision – Many models achieve micron-level resolution.

- Broad material compatibility – Suitable for diverse surfaces including metals, plastics, ceramics, glass, and other common substrates.

In a smartphone assembly line, a laser displacement sensor can detect whether a glass screen is seated perfectly flush with the phone frame — without touching it or interrupting production.

How do laser displacement sensors work?

Most operate using one of three optical principles:

- The core of laser triangulation is the precise measurement of the angle of the returned beam to ascertain distance.

- Range: Typically up to 1 m.

- Strength: Extremely high accuracy.

- Use case: Electronics assembly, small component inspection.

- Range: Typically up to 1 m.

- Confocal (multi-wavelength) – Uses chromatic aberration to focus different wavelengths at different distances.

- Range: Short to medium.

- Strength: Handles transparent, reflective, or multi-layer materials.

- Use case: Glass thickness inspection, film coating measurement.

- Range: Short to medium.

- Distance is derived from the exact time difference measured between laser pulse emission and reflection reception.

- Measurement Span: Extends from several centimeters to tens of meters.

- Strength: Excellent for large targets and outdoor use.

- Use case: Robotic positioning, large equipment alignment.

- Measurement Span: Extends from several centimeters to tens of meters.

Imagine you mount a triangulation sensor above a conveyor belt. As each product passes, the sensor continuously measures its distance. Deviations from the expected value flag dents, bulges, or missing parts — allowing for automatic rejection before packaging.

Working Principles & Measurement Methods

Here’s a comparison of the main methods:

| Method | Strengths | Limitations | Best Use Case |

| Triangulation | Micron-level accuracy, compact design | Limited range (~1 m) | Semiconductor assembly, micro-part inspection |

| Confocal | Handles glass, film, and polished metals | Higher cost | Smartphone cover glass QA, optical lens measurement |

| ToF | Long-range, robust in harsh settings | Lower resolution than triangulation | Positioning gantry cranes, monitoring large presses |

Precision Analysis: How Accurate Are Laser Distance Devices?

High-end triangulation sensors can achieve ±0.1 μm accuracy (Keyence, Technical Data). However, actual performance depends on:

- Surface condition: A rough matte finish reflects differently than a polished surface.

- Environmental factors: Temperature drift can cause micrometer-scale errors.

- Mechanical stability: A vibrating mount can ruin precision.

In an automotive plant, triangulation sensors were used to verify brake rotor thickness. Initial accuracy dropped in summer months due to thermal expansion of fixtures. Adding temperature compensation restored 100% pass/fail reliability — preventing costly false rejections.

Optimal Sensor Selection for Displacement Monitoring

When selecting a laser displacement sensor, consider:

- Measurement range – Match sensor capability to your target’s position tolerance.

- Surface reflectivity – Highly reflective or dark targets may need specialized optics or filters.

- Operating environment – Heat, dust, or oil mist can require sealed housings (IP67+).

- Output format – Analog for continuous monitoring; digital for threshold-based checks.

Tip: Request a manufacturer’s demo in your production environment before purchasing. Real-world testing often reveals hidden challenges that datasheets don’t cover.

Types of Laser Displacement Sensors

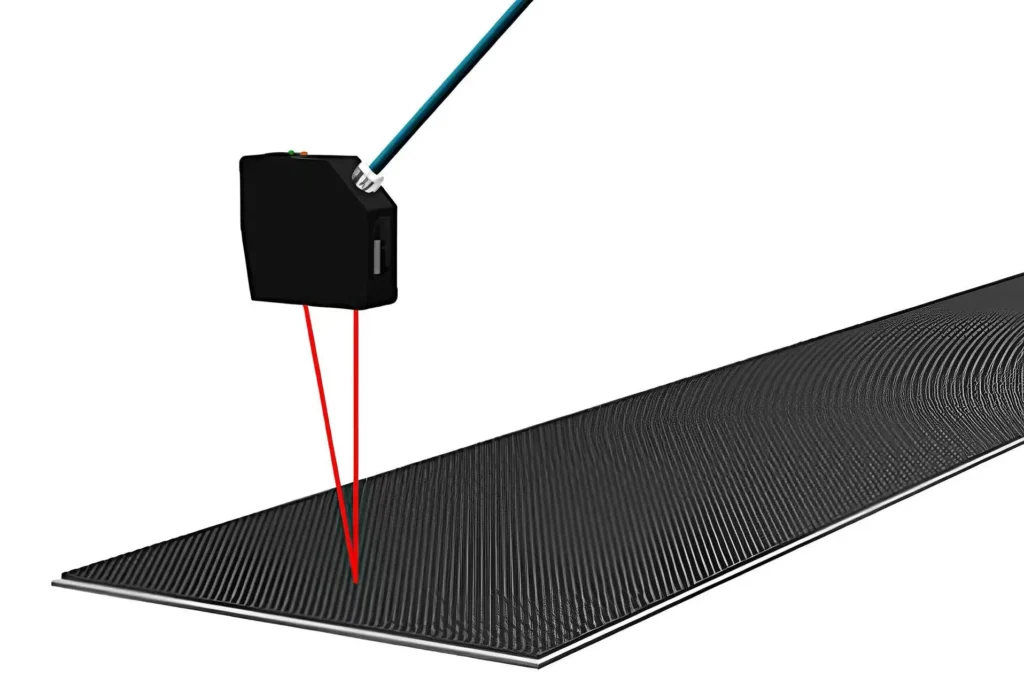

- 1D Triangulation Sensors – For single-point precision measurements.

- Confocal Displacement Sensors – deliver optimal performance on these surfaces.

- 2D/3D Laser Profilers – Capture full surface geometry for gap, contour, and weld inspection.

- Long-Range ToF Sensors – Positioning and measurement at distances over several meters.

Disadvantages & Advantages

Advantages:

- Micron-level accuracy, even at high speeds.

- Non-contact — no physical wear on target.

- Capable of measuring moving or hot objects.

Disadvantages:

- Certain surfaces (e.g., mirror-polished metal) require special setups.

- Higher cost than inductive or capacitive sensors.

- Requires rigid mounting and alignment.

Applications

Laser displacement sensors are used in:

- Automotive Measurement – Disc Rotor Thickness Validation and Structural Frame Alignment Measurement.

- Electronics – PCB warpage detection, display assembly inspection.

- Glass manufacturing – Thickness verification, surface defect mapping.

- Metal Fabrication – Monitoring Material Flatness and Verifying Weld Seam Gap Clearances.

Installation & Setup Guidelines

- Positioning: Mount perpendicular to the target for highest accuracy.

- Lighting: Avoid direct sunlight or bright reflections into the sensor.

- Cleanliness: Keep lenses clean using air blowers or protective covers.

- Calibration: Always test with a reference block before starting production.

How to connect a laser sensor?

- Determine output type: analog, digital, or Ethernet.

- Use shielded cables to reduce interference.

- Follow the wiring diagram in the sensor’s manual.

- Test with your PLC or controller before full integration.

Frequently Asked Questions (FAQ)

How do LiDAR systems differ from basic laser sensors?

Laser displacement sensor – Measures a single point or line for highly accurate distance or thickness readings.

LiDAR – Sweeps a wide area to create a 3D map, sacrificing single-point accuracy for broader coverage.

Can they measure shiny or transparent objects?

Yes — confocal or polarized laser sensors work best.

Do they require regular calibration?

For precision work, yes. Most manufacturers recommend at least once per year.

Can they work in outdoor environments?

Yes, but use IP-rated models designed for outdoor use.

What’s the maximum range?

Time-of-flight models can reach several meters; triangulation is shorter.