Fiber optic sensors are the best alternative to conventional photoelectric sensors, when the installation space is extremely limited or the object to be detected is extremely small.

If you need to meet higher requirements, such as stronger temperature resistance, higher detection accuracy, higher material durability, or more flexible installation methods, the intelligent combination of sensors and optical fiber can give you a satisfactory solution.

What is optical fiber sensors?

Fiber optical sensor is an optical sensor based on optical fibers. It is also a type of photoelectric sensor. It uses optical fibers as the transmission medium to detect various physical parameters such as strain, displacement, color, vibration.

The working principle of optical fiber sensor

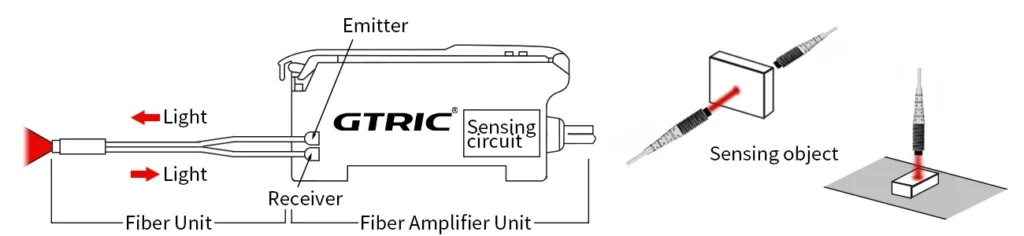

Fiber optical sensor working principle is based on the transmission characteristics of light wave. This type of sensor consists of two units: an optical fiber probe and an optical fiber amplifier.

Fiber optic amplifier sensor emits a light source that is transmitted to the object being detected through one optical fiber (transmitting path). The light reflected by the object is returned to the fiber optic amplifier through one or more optical fibers (receiving paths). The amplifier detects the presence of the object or determines its properties by analyzing the amount or intensity of the reflected light.

Features of fiber optic sensors

1.Exceptional Space Efficiency

The compact probe size of the fiber optic sensor enables it to fit into most confined spaces. With plastic optical fibers offering a minimum bending radius of R25 and outstanding flexibility, the sensor ensures reliable signal transmission even in complex environments. This allows for high-density integration and discrete monitoring.

2. Outstanding Environmental Adaptability

Based on an all-dielectric optical sensing principle, fiber optical sensors provide inherent immunity to electromagnetic and radio frequency interference. It operates stably in high-intensity electromagnetic, radiative, and corrosive environments, with a wide operating temperature range, maintaining excellent stability and temperature resistance in demanding industrial applications.

3. Broad Material Compatibility

Utilizing an optical sensing principle, the sensor overcomes the limitation of traditional inductive sensors, which only detect metallic objects. It reliably and accurately detects a variety of materials including glass, plastic, wood, liquids, and transparent films.

4. Multi-Functional Detection

Different fiber optic amplifier sensors are capable of not only detecting object presence or passage but also identifying multiple colors simultaneously.

5. Modular Configuration

The system supports flexible combinations of fiber optic probes, amplifiers, and focusing lenses. For example, the same diffuse-reflective sensor probe can be paired with switching, analog, or color recognition amplifiers. By selecting appropriate focusing lenses, the spot size and detection distance can be precisely adjusted to quickly meet diverse detection requirements.

6. Easy Installation and Adjustment

The fiber sensor probe and signal processing fiber optical amplifier are separately designed. The probe can be installed close to the measurement point, while the amplifier can be centrally mounted in a control cabinet. This allows for unified adjustment and monitoring, reducing installation and maintenance complexity.

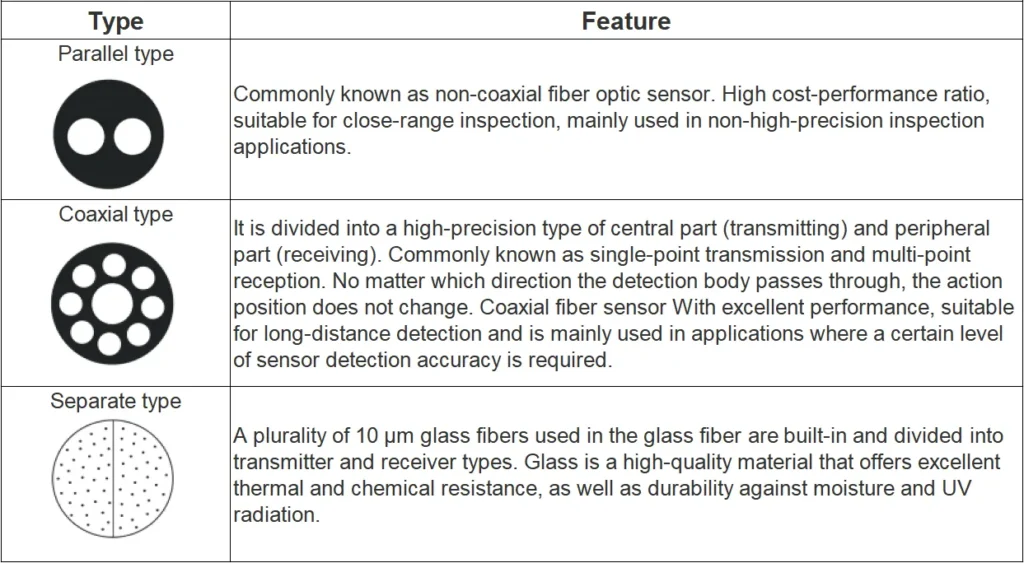

Types of Fiber Cores

1. Plastic type

The core is made of acrylic resin, which is made of single or multiple roots with a diameter of 0.1 to 1 mm, and is wrapped by materials such as polyethylene. Based on its light weight, low cost and not easy to bend, it has become the mainstream of optical fiber sensors.

2. Glass type

Glass fiber optics are often made from high-purity quartz glass. It consists of glass fibers of 10 to 100 μm and is coated with stainless steel. It has the characteristics of high operating temperature (Maximum can reach 350℃). The glass-type reflective type observes its core from the end face, which is generally separated.

Types and Applications of Optical Fiber Sensors

1. According to fiber optic beam transmission, it can be divided into single-point (threaded or cylindrical) and multi-point (array) types and window-style.

1.1 Thread type optical fiber

The fiber optic probe features standard threads (M3, M4, M6, etc.) and is made of stainless steel. It can be directly screwed into pre-drilled mounting holes or brackets. It can be used with a fiber optic focusing lens to focus diffused light into small spots. Installation is quick and easy, with low maintenance costs and high cost-effectiveness.

1.2 Array type optical fiber

By arranging and combining multiple fiber optic sensing units, data can be acquired simultaneously from multiple locations, enabling the detection of large areas or complex structures.suitable for detecting workpiece deviations or complex shapes, and is easy to install with high accuracy.

1.3 window type optical fiber

By integrating the transmitter and receiver fibers of the fiber optic sensor into a combined optical “window”, it becomes capable of detecting objects passing or falling through,particularly suitable for detecting and counting objects falling or moving inside plastic pipes.

2. According to the different detection methods, it can be divided into diffuse reflection type, through beam type, and window type.

2.1 Diffuse-reflective fiber optical sensor

Due to the different surface properties of the object, such as color and gloss and surface texture, will affect the intensity of the reflected light, so the effective distance of the diffuse reflection sensor is determined by the reflection ability of the target. This kind of sensor has simple structure and convenient installation, but the detection distance is relatively short.Different detection distances can be achieved by combining different fiber optic probes, fiber optic amplifiers, and fiber optic focusing lenses.

Practical Applications

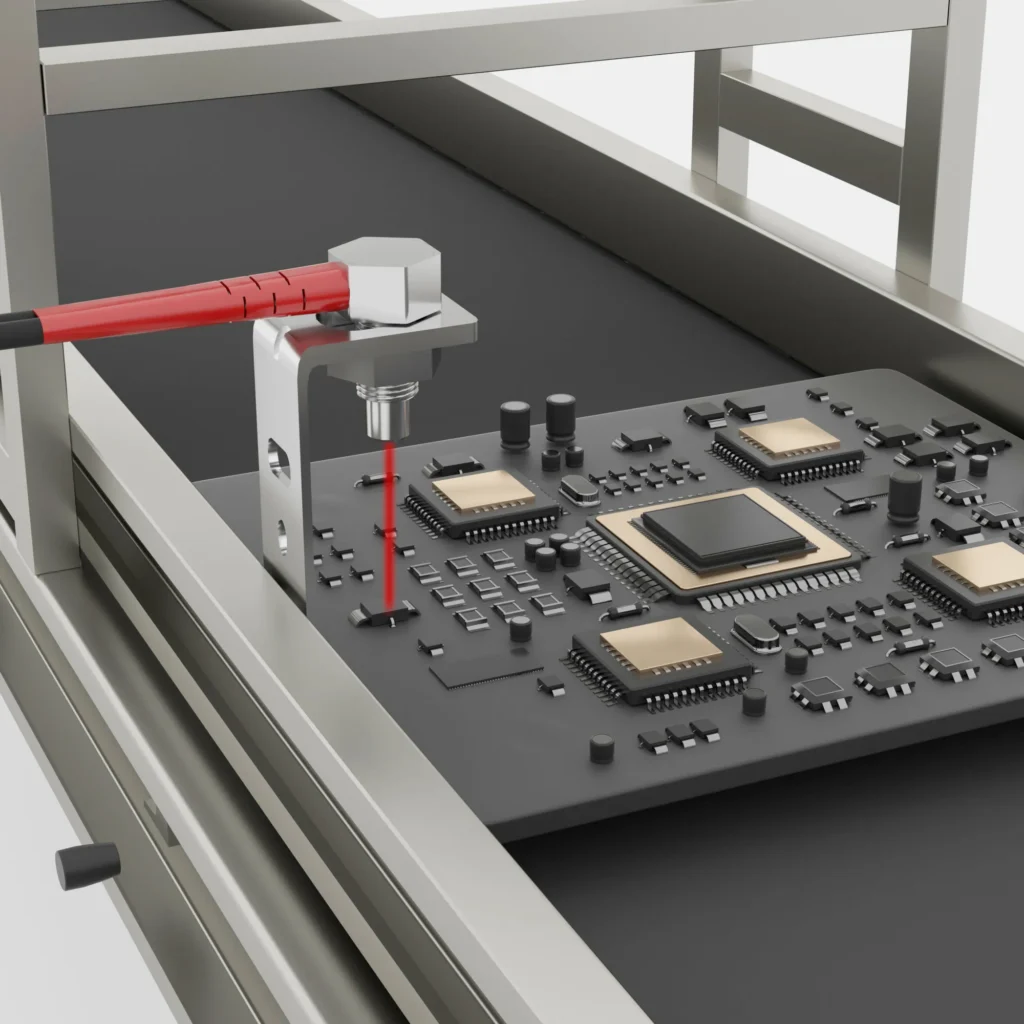

Although the surface object of the PCB board is complex and contains different components, the sensor can overcome the difference of diffuse reflectance and achieve accurate positioning of the board in a short distance by using a focused optical fiber probe.

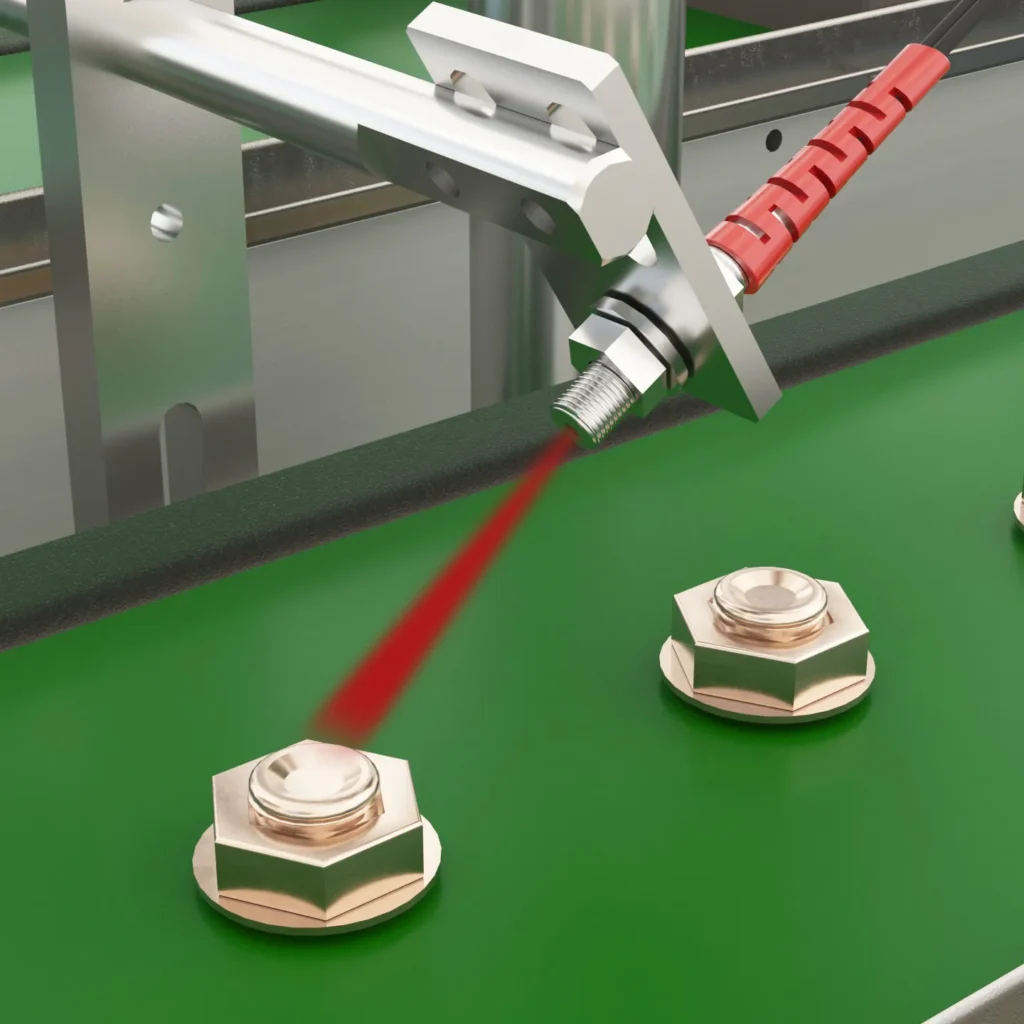

Although the metal surface has high gloss and strong reflective ability, its irregular shape (texture) can easily lead to light scattering. Using the sensitivity adjustment function of the fiber amplifier, the effective reflected light intensity of the metal parts can be locked to complete the stable detection.

2.2 Through beam fiber optical sensor

Through-beam fiber optic sensors separate the components of a diffuse reflection sensor into a transmitter and a receiver, which are typically installed on opposite sides of the object to be detected, forming a direct line-of-sight beam path. When an object passes through this path, the beam is blocked or interrupted, thereby triggering a switching signal. Due to advantages such as long detection range and immunity to the color and reflectivity of the target object, this type of sensor is particularly suitable for applications requiring high precision and reliable detection.

Practical Applications

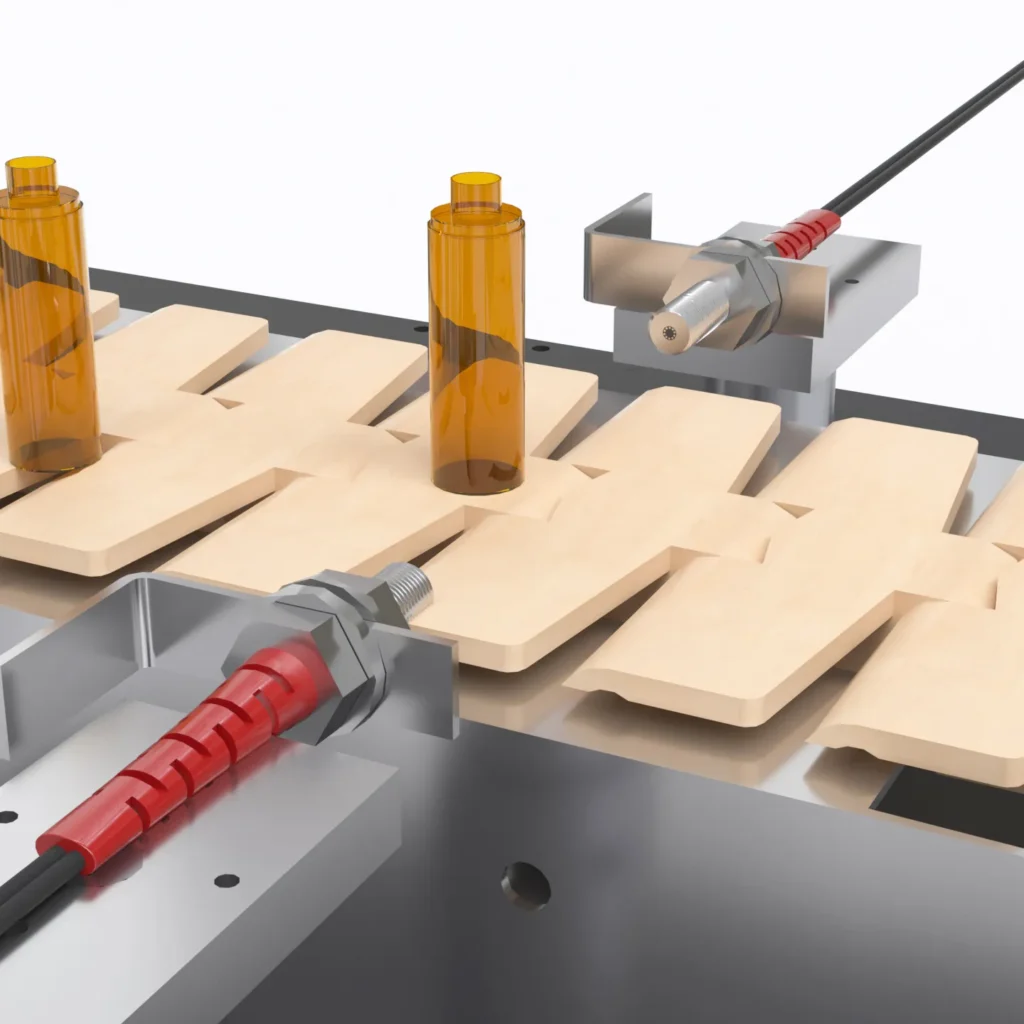

Through beam fiber optical sensor shows excellent performance in the detection of translucent objects (such as infusion bottles, liquid bottles). Although the bottle body is not completely shaded, the light intensity attenuation (Light Attenuation) generated when the beam passes through the bottle body and the internal medium is sufficient to be captured by the highly sensitive receiver and trigger the signal.

2.3 Window-type fiber optical sensor

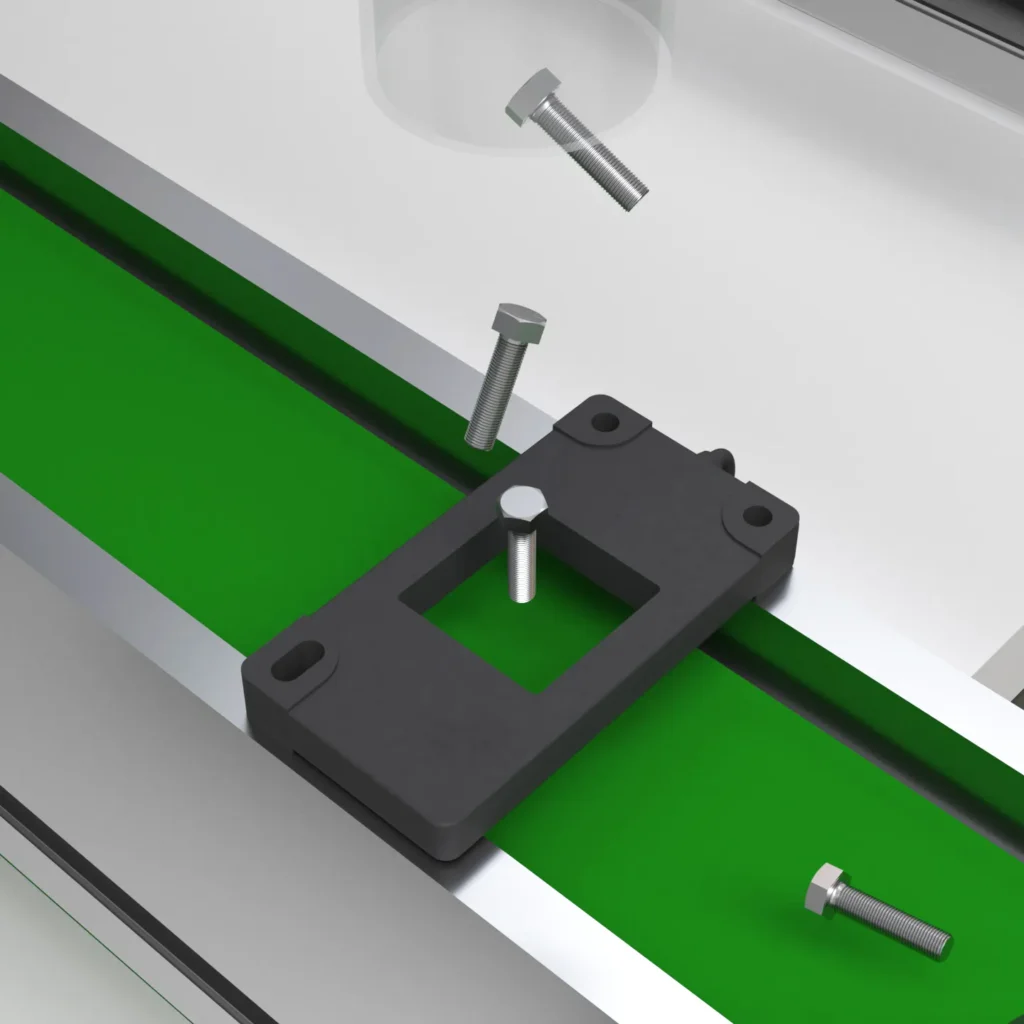

Window-type fiber optic sensors offer the same performance and advantages as through-beam sensors, while addressing the drawback of increased spot pitch in through-beam array sensors caused by a higher number of light spots. Paired with a dedicated amplifier, they can achieve detection of objects as small as 0.1 mm. This makes them highly suitable for detecting objects with varying dimensions, positional deviations during movement, or objects moving within a specified area.

Practical Applications

When detecting small workpieces such as metal screws and nuts that are prone to position offset, the Window-type fiber optical sensor shows its unique advantages. The workpiece will inevitably jitter during falling or transmission, and the ordinary single-point beam is prone to missed detection. The ‘area array’ beam of the window sensor covers a rectangular area, and as long as the workpiece passes through any position in the window, it can be stably intercepted.

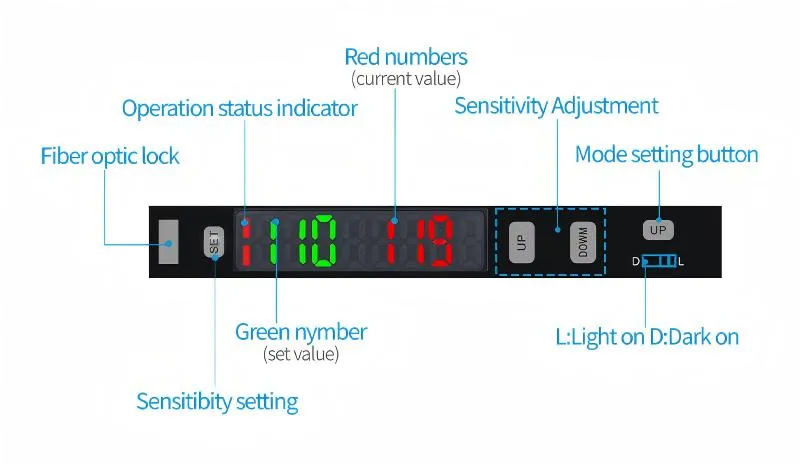

Fiber Optical Amplifier Sensor

Fiber optic amplifier sensors serve as a key component in fiber optic sensing systems. They integrate a light source (LED/laser), a light receiver, and signal processing electronics. The operating principle involves emitting light from the sensor’s source through a fiber optic probe onto the target object. The light signal is either obstructed (through-beam) or reflected (diffuse reflection), and a separate fiber collects these signals and transmits them back to the amplifier. Upon detecting variations in the light, the amplifier converts them into actionable electrical signals (on/off output).

Types of Fiber Optic Amplifier Sensors

At GTRIC, our fiber optic amplifier sensor portfolio includes not only models with digital switching outputs (NPN/PNP) but also versions with analog outputs (0–5V). Additionally, we offer specialized color fiber optic amplifier sensors. These color sensors can simultaneously detect and differentiate up to four distinct colors, with the capability to precisely identify minute variations in hue. This makes them ideal for production environments where exceptional color consistency is required.

How to select and install fiber optic sensors ?

Due to their versatility and adaptability, fiber optic sensors offer a variety of options for different environments.

- Operational Environment: Determine the intended operational environment or scenario for the fiber optic sensor. Consider whether it is a specialized setting, as the functional parameters of different sensor types vary significantly under diverse environmental conditions.

- Application Method: Clarify the intended use of the sensor within that environment—whether for distance measurement, color detection, or object passage sensing. Different fiber optic amplifiers offer distinct output functionalities tailored to specific applications.

- Accuracy Requirements: Higher measurement accuracy contributes to a greater overall precision coefficient for the system. However, sensors with the highest precision are not universally optimal for every scenario. Selection should be based on identifying the most suitable sensor type for each specific application requirement.

- Installation Requirements: Fiber optic sensors are available in multiple configurations. Compact probes enable installation in most confined spaces for object detection, array types are designed for large-area or complex structural monitoring, and window-style sensors detect objects passing through or falling. Different sensor designs are suited to varying application scenarios.