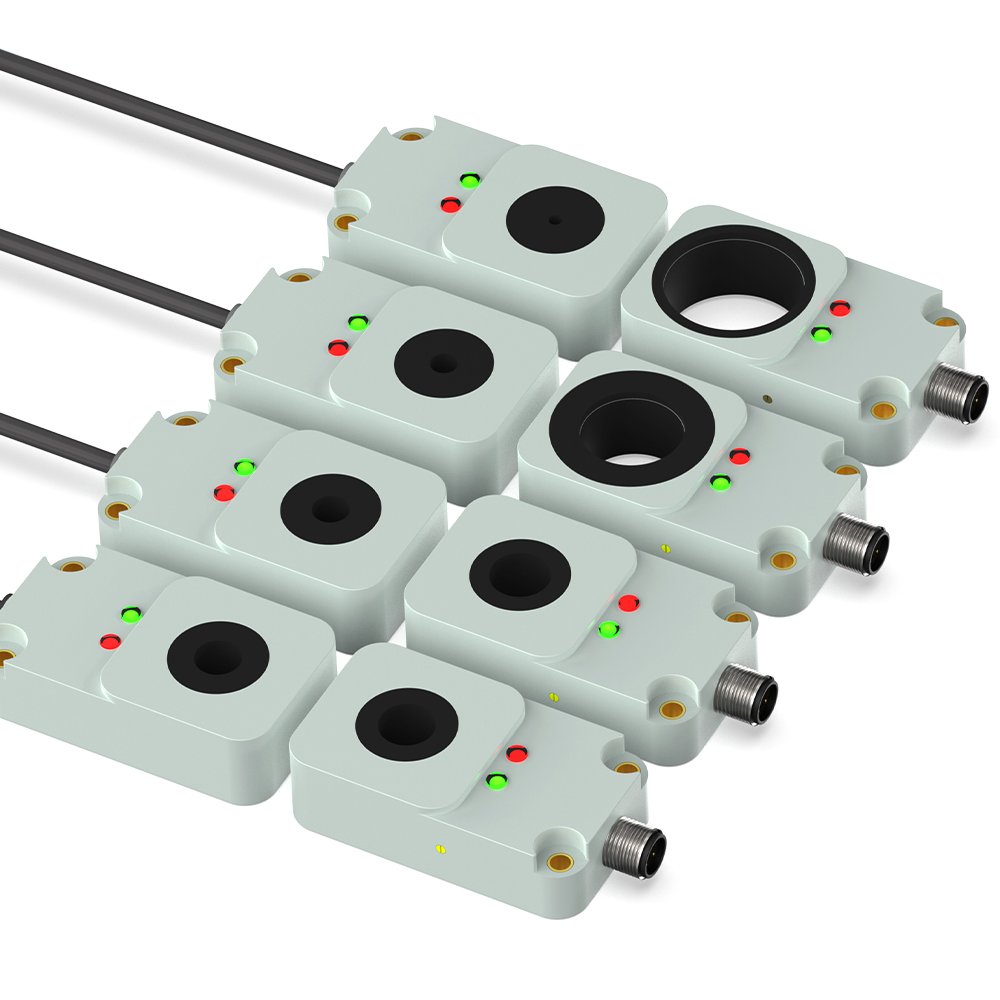

These purpose-built industrial sensors detect movement or presence within their central aperture using proximity sensing technology. Unlike flat-face proximity sensors, these units surround the target path, ensuring detection from all directions.

They’re the unsung heroes of production lines, especially where small or elongated materials—like wires, screws, or tubes—need to be monitored without physical contact.

What is Ring Proximity Sensors?

At their core, ring proximity sensors operate on the principle of detecting objects within a defined electromagnetic or electrostatic field. The key difference from standard sensors? Instead of guarding one point, they guard a passage.

They excel in:

- Wire and cable manufacturing – Detecting every strand in real time.

- Assembly lines – Spotting missing pins, bolts, or caps before the product moves forward.

- High-speed sorting – Counting thousands of parts per minute without wear.

Example: A German automotive supplier integrated ring proximity sensors into its engine assembly line. The sensors checked that each cylinder received the correct number of piston pins before the engine moved to the next station. This reduced costly rework incidents by 28% in six months.

Core Concepts and Design Architecture

A ring proximity sensor typically includes:

- Ring-shaped housing – Built from stainless steel for durability or polymer for chemical resistance.

- Internal sensing coil or plate – Generates the detection field.

- Electronics module – Processes signals and triggers output.

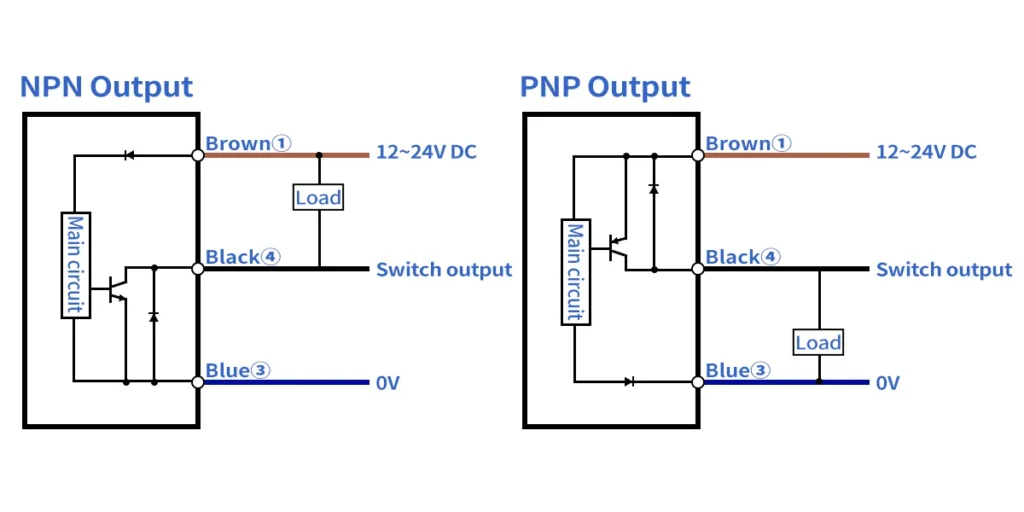

- Output connection – PNP/NPN, analog voltage, or relay for PLC integration.

Diameter range: From compact 10 mm for micro-component detection to large 150 mm models for tubing or cable bundles.

Design insight: Larger diameters offer more clearance but reduce sensitivity. Choosing the smallest workable ring diameter improves detection accuracy.

Key Features & Technical Specifications

Typical parameters to review when selecting a sensor:

- Detection method – Inductive (metals only) or capacitive (metals, plastics, glass, liquids).

- Inner sensing diameter – Matches or slightly exceeds the largest object in your process.

- Response time – Often less than 1 millisecond, critical for high-speed lines.

- Temperature range – Usually -25°C to +70°C; special models can go beyond.

- Ingress protection (IP) – IP65–IP67 for dust and liquid resistance.

Practical note: In oily or dusty conditions, an IP67-rated housing prevents false triggers caused by contamination on the sensing face.

Working Principle

The sensor detects changes in its electromagnetic or electrostatic field when an object passes through the ring:

- An alternating current passed through a coil induces a correspondingly varying magnetic field. Conductive objects (metals) create eddy currents, changing the coil’s impedance. This shift triggers a detection signal.

- Capacitive models – Measure changes in capacitance when any material enters the detection zone.

Case Study: A cable factory reported frequent spool defects caused by broken strands. After installing inductive ring proximity sensors on the feed line, the system halted production instantly when a defect passed through. This reduced waste by 35% and improved quality control.

Types of Ring Proximity Sensors

- Inductive Ring Sensors – Ideal for detecting metallic targets in fast-moving lines.

- Capacitive Ring Sensors – Detect metals and non-metals, useful in mixed-material processes.

- Split-Ring Sensors – Hinged designs allow installation without cutting or disconnecting the target material.

- High-Speed Models – Designed for ultra-fast detection, such as counting 500+ parts per second in sorting facilities.

Advantages and Limitations of Ring Proximity Sensors

Advantages:

- No physical contact — zero wear, less maintenance.

- 360° detection field prevents “blind spots.”

- Handles very high processing speeds.

- Works in compact spaces where flat sensors can’t fit.

Limitations:

- Inductive types can’t detect non-metal targets.

- Capacitive types may be influenced by dust, moisture, or temperature drift.

- Fixed inner diameter requires correct sizing from the start.

Applications

- Wire Processing – Detecting missing strands in cable manufacturing.

- Food & Beverage – Checking for cap presence on bottles moving at 1,000+ units/minute.

- Sorting Systems – Counting bolts, washers, or bearings at high speed.

- Textile Production – Detecting missing threads in automated weaving.

Tutorial:

Set up an inductive ring sensor on a small conveyor. Pass different-sized bolts and washers through the ring while logging detection times. Compare performance between high-speed and standard models to understand the trade-offs.

Selection & Installation Guidelines

Choosing the Right Sensor

- Material compatibility – Match sensing type (inductive/capacitive) to the target.

- Clearance – Select a ring diameter 5–10 mm larger than the largest target.

- Speed requirements – Confirm the sensor’s response time against your line speed.

- Environment – Consider sealing and temperature limits.

Installation Tips

- Mount sensors rigidly to avoid vibration interference.

- Keep away from strong magnetic fields or heavy power cables.

- Center the target path through the ring for consistent results.

Care, Diagnostics, and Fault Resolution

Routine care:

- Wipe sensing areas to prevent buildup of dust, oil, or residue.

- Verify alignment during scheduled maintenance.

- Test detection with a reference part weekly to ensure accuracy.

Common problems:

- False triggers – Often caused by nearby moving metal parts; adjust mounting location or shielding.

- Missed detections – May be due to target size or exceeding sensor speed limits.

Frequently Asked Questions (FAQ)

Q: Can a ring proximity sensor detect non-metals?

A: Yes, but only capacitive types can detect non-metallic materials such as plastic or glass.

Q: How do I size the inner diameter?

A: Measure your largest target and add 5 mm clearance to ensure smooth passage without scraping.

Q: Are they safe for operators nearby?

A: Yes. They operate at low field strengths that meet industry safety standards.